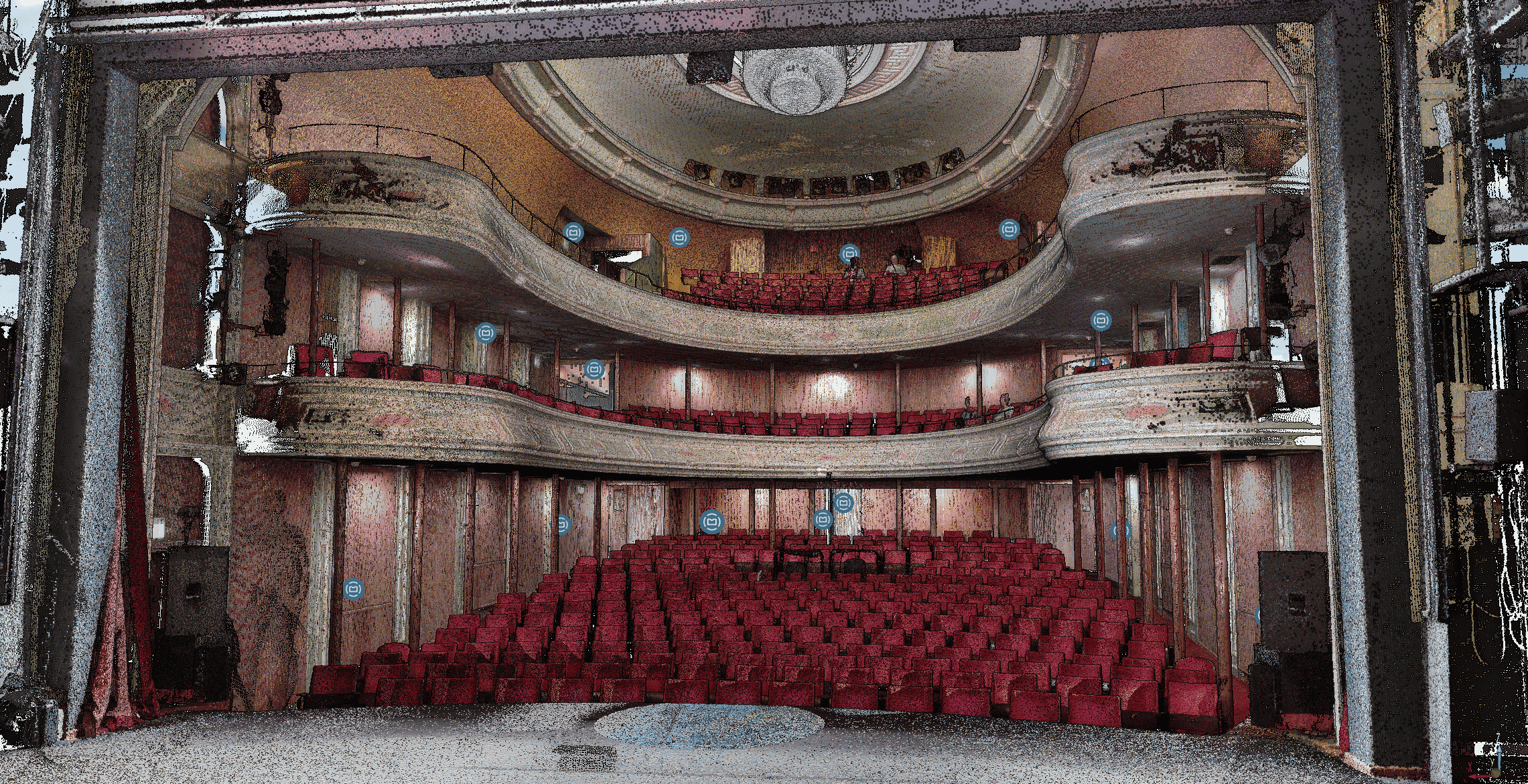

Laser scanning

(3DLS) is a technique that is increasingly being applied in many different fields. This technique makes it possible to record existing situations in detail. A scanner is a measuring instrument, the measurement is made using a laser beam. The environment is converted into pixels, these pixels are points that are reflected back. This produces a point cloud of tens of millions of points, each of which has an x, y, z and reflection value. The laser measurement data is collected based on the distance from the measured point to the laser. Laser light leaves the emitter and reflects off an object where it is scattered. The light that is reflected is captured by optical instruments. With Faro as our main supplier, we have now arrived at the 5th generation of scanners with a unique combination of speed, accuracy and resolution. The compact and lightweight scanners can be taken on the plane as hand luggage and therefore enable us to provide our 3DLS services worldwide at low costs.

Faro Premium 3D scanner can be used anywhere

Thanks to its compact dimensions and lightweight, the faro 3D scanner is ideal to take with you on the plane. Our services can therefore be used anywhere in the world. Curious about the possibilities? Then make an appointment with our 3DLS experts.

3D laser scanning accuracy

The accuracy depends on the technique used. The range we can offer varies from ±0.1 mm for object scanning, ±1 mm (within a scan) for scanning of buildings and process installations to a few cm for drone mapping (when linking recordings, the inaccuracy can amount to a bit). minimum). Our many years of experience have shown that deviations across the entire scan model remain limited and perfectly meet the requirements for our customers’ applications. As standard, we create an accuracy registration report of the scan model. Factors that affect accuracy include:

- Surface reflectivity

- Texture of the material

- Vibrations

- (Sun)light

- Temperature

- Fabric

3D Scan Model

All scans made are linked to one or more models, using reference points or other linking techniques. The model comes with free viewer software that allows you to view, measure and export scans. We also provide training to learn how to use the viewer software optimally and thus get the most out of your scan data. With the scan model you have the cheapest form of very valuable information. However, the scans are just like crude oil, you must be able to refine it to extract the valuable information. Naturally, after so many years of experience, we have mastered this process like no other and have seen all the potential pitfalls.

Want to know more about laser scanning? Make an appointment!

Read more...

Read more... Read more...

Read more...