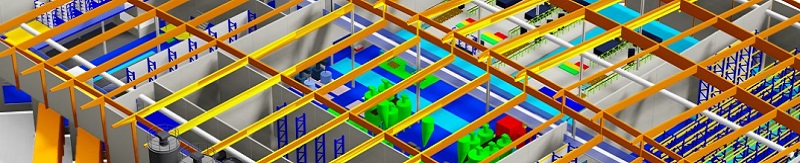

Layout Planning

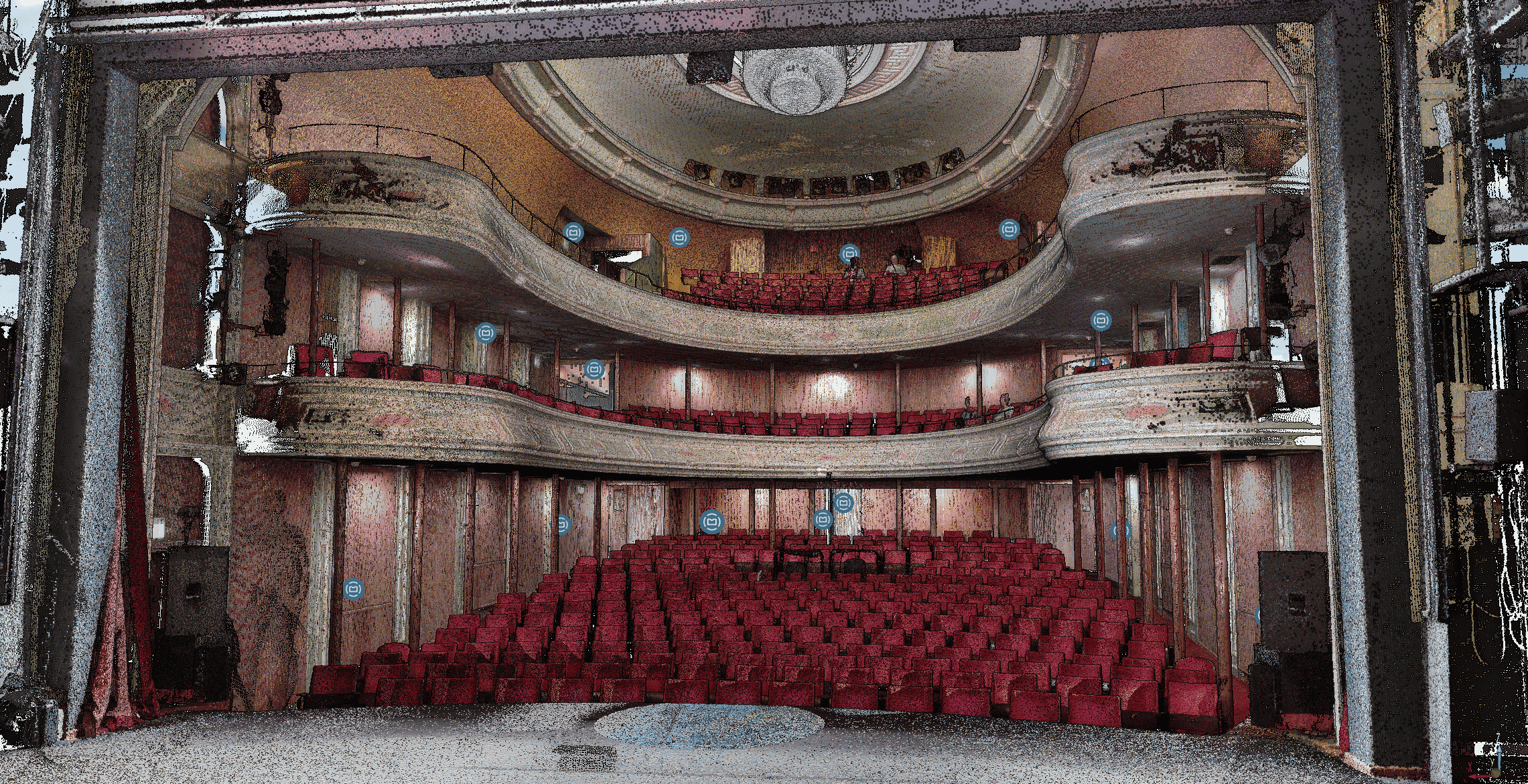

3D scans and scan models provide an excellent basis to:

- Update layouts (for internal engineering or suppliers)

- Reduce measurement costs (via external parties)

- Integrate new installations into a CAD environment

- Virtually reposition existing installations within a CAD system

With years of experience designing factory layouts, we at Ergo Design – Industrial Engineering – also provide support in layout planning and production line design for the manufacturing industry.

What is Layout Planning?

Layout planning involves determining the optimal physical arrangement of all resources that occupy space within a facility. These can include:

- Workstations

- People

- Office spaces

- Cabinets

- Desks

- Departments

Reasons to revise a layout may vary — from the addition of a new department or facility to reorganizing resources to boost productivity. Space reduction may also prompt layout optimization.

The Path of Least Resistance: SLP

Systematic Layout Planning (SLP) focuses on the fastest flow of materials to produce a product with the fewest possible costs and actions — promoting throughput speed. SLP is commonly used in construction projects, where optimal use of temporary facilities is crucial, minimizing waste in time and energy.

Discuss your layout goals with our team and schedule an appointment with 3DLS.

Want to learn more about whether or not to convert your 3D scan data? Leave your details on our website and we’ll call you back!

Read more...

Read more... Read more...

Read more...